You can rely on STERAC

What is it that actually makes STERAC better as a logistics service provider? What differentiates us from the competition? How do we play to our strengths particularly effectively?

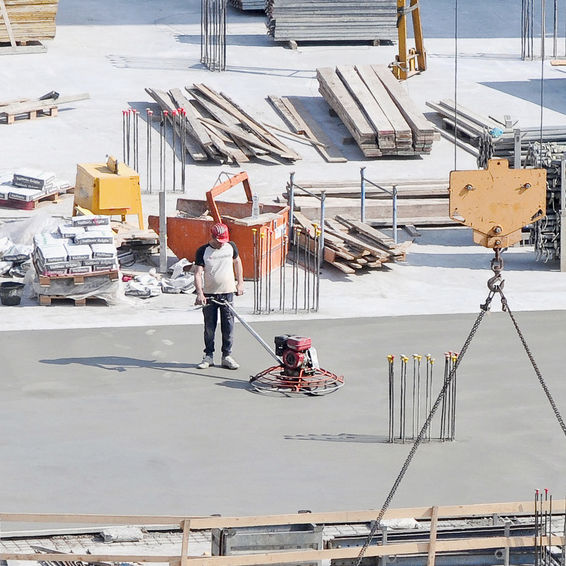

A good example of our expertise in Great Britain and Ireland can be found in our logistical involvement in the construction of the Wathegar Wind Farm in the most northern region of Great Britain. The project had a total investment volume of 15 million pounds.

Through the use of our company's own GPS-monitored trailer fleet (certified according to code XL) we are largely unaffected by cargo space shortages, which is absolutely essential for the constant supply of construction sites and seamless construction site logistics, as is our daily departure frequency. Our team of native speakers remained in constant contact with the construction team on site, in order to guarantee delivery schedule compliance and planning security during the entire project phase. This meant that we were able to deliver a seamless logistics service that adhered to the highest level of quality. Similar haulage transport and projects were also completed with destinations in Wales, Scotland and even Northern Ireland / Ireland.

Another advantage for our customers was our maximum load of 29 tons instead of the otherwise standard 25 tons. This is made possible by the use of inter-modal seaport-hinterland transportation with Cuxhaven. The topic of Green Logistics warrants a mention here.

The project had to be supplied with the most varied goods and types of merchandise. Logistical challenges ranging from hazardous goods transport with paints, lacquers or batteries to large-scale and excess length transportation for sections of the tower all had to be met and overcome. Just like the short-term spikes in capacity, high-value goods also presented us with no problems at all due to our theft protection system (integrated wire netting into the trailer curtain). And even if components were sometimes forgotten, our 24-hour / 48-hour pallet service meant that we were able to organise subsequent deliveries within a very short space of time, ensuring that there was no downtime except, of course, for freak weather events. Returning the racks used for transporting the blades as a re-import was just as much a part of the challenges we faced as was our own trailer standby system, i.e. the de-coupling and subsequent transit of so-called mega trailers or 13.6m curtain-side trailers on the construction site or the loading ramps at the production sites.

Our customers found our proactive information policy to be particularly useful. Thanks to the data link created in-house and the constant online status by the web portal, our customers enjoyed full transparency with regard to the logistics flow. Even if something did not work as planned, our customers were always kept in the picture. Last but not least: given our good connections with local decision-makers we were able to contribute to ensuring that the project was completed on time and without any significant complications.